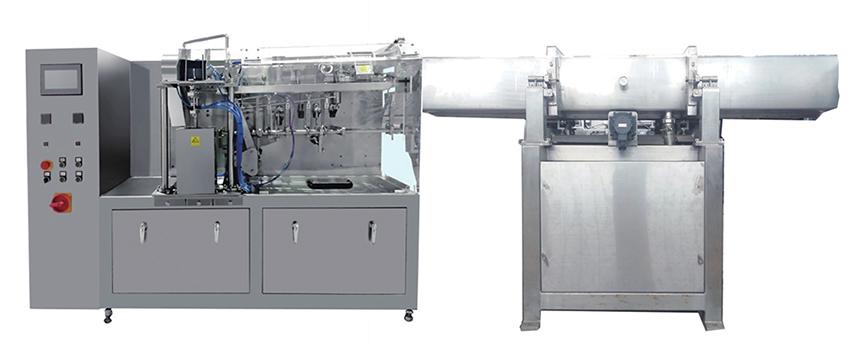

JDZ-180D/240D, Pre-made bag Rotary System Pouch Packaging Machines

The JDZ-180D/240D pre-made bag rotary system pouch packaging machines produce 2 pouches in each production cycle, at twice the speed of the JDZ-180/240. In addition, this rotary system pouch packaging machine type features a vacuum function, which keeps air out, avoids food oxidation and spoilage, making them ideal for food packaging.

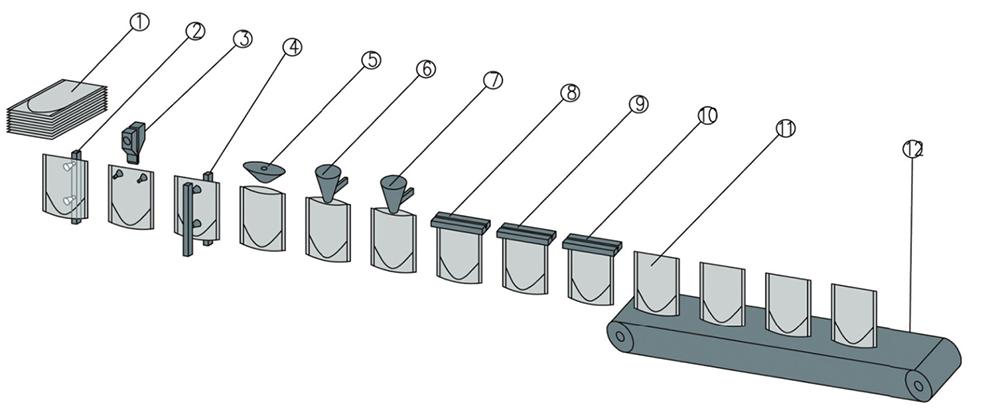

1. Premade Pouch Stack

2. Flip-Out Pouch-Picking

3. Zipper Opening

4. Pouch Opening

5. Air Flushing

6. Filling Ⅰ

7. Filling Ⅱ

8. Top Seal Ⅰ

9. Top Seal Ⅱ

10. Cold Seal

11. Finished Product

12. Product Outlet

| Type | Minimum Bag Size (mm) | Maximum Bag Size (mm) | Packing Capacity (ml) | Packing speed (ppm) | Power (kw) | Gas consumption (NL/min) | Weight (kg) | Equipment Size (mm) |

| JDZ-180D | 80*110 | 90*230 | 500 | 100-120 | 10 | 350 | 3600 | 8000*1300*1500 |

| JDZ-240D | 100*240 | 120*320 | 800 | 100-120 | 10 | 350 | 3600 | 8000*1300*1500 |

· Independent Film Unwind Unit

· Better doypack forming

· Ensure good control of film tensile force

· More flexible and suitable for different pouch specifications.

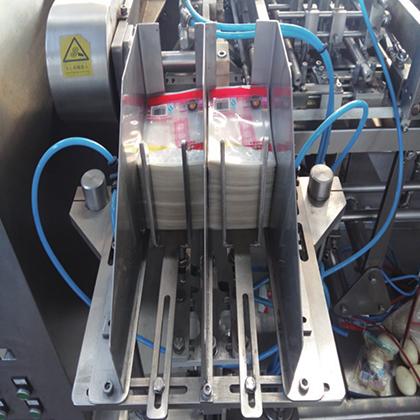

· Dual Filling Station

· Improved filling accuracy

· Fill 2 products simultaneously

· 2 Top Seal Unit

· Ensures the seal strength and no leaks

· Even seal with sleek appearance

· Higher film material adaptability

For more than 2 decades, Jiadi has been providing customers with food processing line solutions. We offer outstanding processing and packaging solutions for tomatoes, mangoes, apples, bananas and all of your other favorite foods.

Thanks to significant industry experience and advanced technology, we can deliver customized food processing lines to meet your various food production requirements.

Whether you are looking for a single machine or a complete food processing line, Jiadi is here to satisfy all of your requirements.

Food Processing Lines - Tomato Paste Production Line

- Mango Pulp Processing Line

- Fruit Juice Concentrate Production Line

- Tomato Powder Production Line

- Banana Powder Production Line

- Fruit Juice/Tea Drink Production Line

- Pasteurization Milk/Yoghurt Production Line

- Milk Powder Production Line

- Other Fruit Processing Complete Processing Line

- Pouch Packaging Machines

- Main Machine

- No.500, Chunnong Road, Huangdu Industrial Park, Jiading District, Shanghai

-

- Tel.: +86-21-69592083

- Fax: +86-21-69590351